Project Logistics Control Centres (PLCC’s), what are they? How do they operate? XELLZ, a company in-the-know when it comes to using digital solutions to optimize operations, has much to share on the subject including the limitations to technology and the value of the human factor.

Regardless of the technologies or solutions we use today, and no matter how superior AI and automation systems become, in the project logistics industry we all still depend strongly on the human factor.

XELLZ believe that all the systems they have created, technological or otherwise, have one basic common drive, “to make things easier for us, our customers, and for the projects we control.”

By forgetting this core principle and taking things a bit too far, experts have started to try to implement fully-automated complicated systems as so-called inevitable infrastructural requirements for modern times. When it comes to developing beneficial PLCC’s, there is a fine balance that must be found between human and technological factors.

What is a PLCC?

The Project Logistics Control Centre is the “mission control” centre that brings all information and communication together into one online location and creates a single point of collaboration eliminating duplication of work. It is a critical environment operated by a team of people with 100% control, productivity, transparency, and efficiency to ensure the success of projects for multi-disciplined organisations.

For O&M, installation and logistics, XELLZ uses these control centres to optimise operations with meticulous planning, control and monitoring. According to XELLZ, the average project has a 35% cost and 7% time overrun rate and delivers 55% less value than expected. By establishing a PLCC, projects can remain 100% in focus, which means less overruns and finishing projects with value and within schedule.

“A typical non-stop 365-day 24/7 PLCC is monitoring and controlling the flow of several project logistics information streams at the same time. Communicating with related remote locations and on the ground field-managers, guiding them from the core and taking action if needed.”

PLCC’s in Practice

Like their other innovations, XELLZ have started using Project Logistics Control Centres for different industrial sectors. The concept can be used for various purposes with one aim: controlling all resources within reach and act when the need arises.

In any industry related to capital projects, millions of dollars are allocated to the optimization of the engineering, design and production parts and elements that make up the project. For offshore projects, logistics seems to be a side of the business that is not closely focused on and thus investments in the logistics aspect of the projects are underestimated and underfunded.

Control towers are more common in relation to logistics. Attention is given to the control of shipments where planning and track and trace are important. This can, for the most part, be automated through AI and other technological solutions.

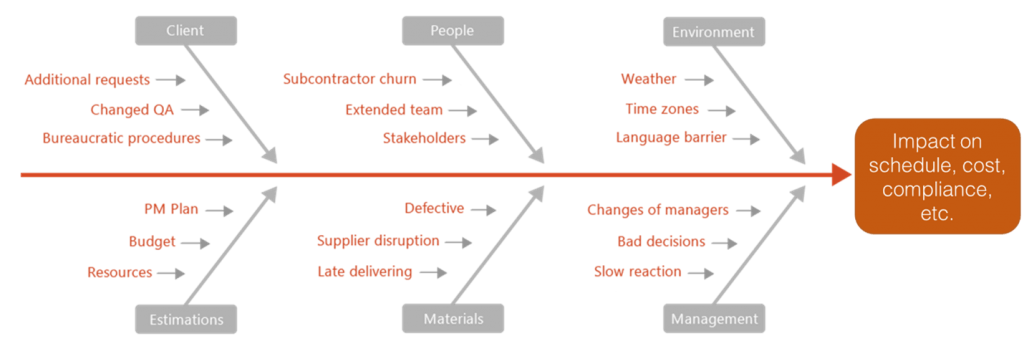

Project logistics however is never the same. There’s too many variables and controlling them is a whole different discipline altogether. It requires Project Control Centres through which an overview can been be seen centrally and immediate action can be taken if necessary.

PLCC’s are the perfect fit to see the big picture through all lenses of the project and leave nothing in the shadows. This enables a safe and timely risk-analysis which is a major factor in getting the “element of surprise” under control.

PLCC’s Positives

PLCC’s provide advantages for many different industry sectors that require logistics monitoring with the ability to take control over in an instant if necessary.

Peter Bouwhuis, CEO, XELLZ says, “One of the main advantages of our PLCC’s is the ability to bring many different disciplines together and establish connections between them. That way, project logistics managers can be in control of all different sources at the same time. Without these logistics control centres, every discipline would need a different source to try and collaborate with each other, resulting in a significant loss of time and high costs.”

All in Order

Even though many companies are able to work the logistics on their own or with a freight forwarder on a daily basis, they still need to constantly check the project logistics operators. The PLCC is there to monitor all movements, actions, documentation, surveys, and other reporting continuously.

Production lines need to be under control to prevent unwanted outcomes. Source & inventory control, factory automation systems and all infrastructures should be under control in order for operations to flow.

“Many millions are spent optimizing these processes. However, I see too many times that the logistics is not getting as much attention as it should. Logistics is a vital link in any process or project and should never be taken lightly.” says Bouwhuis.

PLCC’s direct ships, trucks, aircrafts and any other transport or element that is needed for the project as well as other relevant resources to reach the job site on time. During crisis situations such as natural disasters, coordination between the project logistics centres can potentially prevent project failure and save significant financial loss.

Depending on the needs of different sectors and requirements of physical environments and technologies, the devices used in Project Logistics Control Centres can vary. However, many of those core technologies such as ProjeXsmart™, operator stations, security, [route] survey and or inspection reporting protocols stay the same.

Results

Results show that control and focus are heightened, and any action taken by the team in charge is proactive instead of reactive. As is the case in most projects, being proactive mitigates risk and avoids a crisis.

“Getting a project finished in time and within budget has always and still is the goal that we all strive for, so let’s look at technology as an aid to logistics control and not to automate the control.”

Technology is needed and digitization is essential when operating offshore or onshore projects. The logistics is too complex and subject to constant change and outside influences that would easily disrupt a more manual process. A digitalised Project Logistics Control Centre operated by a team is the best approach.

Technology helps improve the project focus and control in many ways, but it should never be forgotten that this cannot be achieved without human intelligence. We should think twice about eliminating manpower from complex processes to rely solely on technology.

Team of Xellers

XELLZ are tackling new challenges and transitioning project logistics into a smart sector the “XELLZ way” with transparency, trust and technology.

Headquartered near Amsterdam, XELLZ provides worldwide project logistics management from their offices in the Netherlands, the U.S., Ireland, Nigeria and Germany.

The XELLZ team is currently busy with four upcoming ‘Energy Transition’ projects in Germany and the US, the largest of their kind in these countries. XELLZ is also making headlines with its early involvement in offshore wind farms off the coast of Ireland, where 24shore (a division of XELLZ) has secured over 300.000m2 of land at the port of Rosslare. XELLZ Ireland Ltd. is in discussions with energy companies and others interested in the installation of these offshore wind farms. 24shore will also develop the European Business Park (EBP) on the land connected to the port area with direct access to the quay and will be used for offshore supply base operations including pre-installation assembly and mobilization. The area also offers SME’s a space to locate their business during and after the construction and maintenance & repair.

www.XELLZ.com

Source: Oil&Gas Innovation, Winter 2021: https://issuu.com/edwardogi/docs/ogi_winter_2021_light/42

Written By: Joanne Kelleher